Major shopping holidays like Black Friday, Cyber Monday, and Mother’s Day continue to bring flocks of customers ready to spend, despite issues like inflation. In 2022, U.S. shoppers spent $35.3 billion across Cyber Week, and that’s just online.

Whether you’re a manufacturer, distributor, brick-and-mortar store, or e-commerce retailer, shopping holidays are excellent opportunities to increase your sales and boost revenue. That is, as long as you’re able to manage sudden increases in seasonal and holiday consumer demand well.

Businesses that can’t quickly respond to increased demand effectively and efficiently run the risk of higher costs, lower profitability, and poor customer experiences that can result in lost sales.

Using technology to improve responses to shifting demand, manage seasonal inventory stock levels, and better predict future demand helps you take advantage of your busy season.

Let’s dig into the common challenges associated with seasonal demand forecasting and inventory management, as well as solutions to help you master major seasonal shifts.

Here’s what we’ll cover:

> Top challenges of seasonal demand forecasting

> How Cin7 helps sellers capitalize on major sales and holidays

> Final thoughts: The top 6 holiday challenges for sellers + how to solve them

Seasonal demand forecasting uses past sales data to predict customer demand during more volatile times like holidays and for seasonal demand spikes, such as summer beach products, by looking at past trends and projecting them forward with adjustments.

Beyond forecasting sales during the holiday season, it can also be used to help sellers prepare for any other busy times of the year. For instance, swimwear sellers might use it to prepare for the Spring and Summer seasonal product interest spikes as the weather warms up and people look forward to the beach.

During holiday seasons and special events, consumer demand may spike suddenly. The added volatility makes sales harder to forecast while also putting extra pressure on your operations to fill many more orders in a short time.

Here are the top six seasonal challenges that make it more difficult for sellers to predict and meet customer demand accurately.

When planning for a spike in consumer demand, your goal is to hit that sweet spot of having enough stock to fulfill orders without ordering so much you can’t move excess product.

It’s essential to have access to accurate stock levels in real-time in order to achieve accuracy in your seasonal demand forecasting.

If you don’t know what you already have, making intelligent, data-driven decisions for major shopping holidays like Black Friday is nearly impossible. Using spreadsheets and outdated software for inventory management can make it harder to get real-time insights about your stock levels so you can confidently place orders for what you actually need.

Temporarily ramping up production capacity ahead of expected future sales for seasonal holiday shopping like Valentine’s Day, Mother’s Day, and Christmas can be difficult while maintaining quality standards, especially with products that have a short shelf life.

Waiting until after demand occurs to scale up your operations can lead to problems with staffing. And that is compounded when we look at the continual issue of labor shortages in the supply chain, as seen in this survey by Ivanti Wavelink, where 57% of supply chain professionals listed labor shortages as the biggest challenge they’re facing right now. When trying to scale up on short notice, those widespread labor shortages become particularly difficult to deal with due to compressed timelines.

For e-commerce retailers, these challenges may look like understaffed warehouses and a lack of delivery drivers. For manufacturers, it may be undertrained seasonal forklift operators, running out of materials on a production line, or no room to manage higher stock levels waiting to ship.

Either way, not having enough resources, including staff, can lead to orders piling up, dangerous working conditions, shipping delays, unhappy customers, and a loss of profits.

Bottlenecks are never a good thing for your operations. But during major shopping holidays, peak seasons like Christmas, and large sales, these bottlenecks are more likely to happen, and they have a more significant impact on your business.

A single bottleneck can negate the rest of your efficiency efforts. For example, suppose you maximize staffing in your order picking and packing department but understaff your inventory stockers. In that case, your order pickers won’t have anything on the shelves to pick, pack, and ship because the stockers can’t keep up.

From a technology standpoint, using spreadsheets and manual tracking processes creates bottlenecks as each step must wait on manual counts and data entry.

Both physical and technological inefficiencies in your operations can cause additional costs that eat into your profits. They can also result in delayed order fulfillment, creating a negative impression on customers and may even lead them to switch to a competitor’s brand.

As such, sellers need to optimize production processes, reduce lead times, and eliminate waste to avoid bottlenecks and stay profitable during busy seasons.

Unlike regular shopping seasons, sales and holidays create large spikes in demand that sellers only have a short window to capture. Given that there’s not a long time period to respond to an increase in orders, you have to prepare ahead of time by predicting how much customer demand will increase.

That being said, seasonal changes in demand can be volatile due to the economy and shifting consumer demand patterns. For example, is chartreuse or orange the new black this season?

Without the right historical sales data and demand forecasting models, it can feel almost impossible to know what sales volume to prepare for. If you overestimate, you can end up with an overstock of dated products, and if you underestimate, you’ll miss out on sales opportunities.

In Blue Yonder’s 2023 Supply Chain Executives Survey, 87% of respondents reported that they experienced supply chain disruptions over the past year, often resulting in customer delays.

These disruptions remain common and can have serious consequences for sellers. One Deloitte report found that 50% of manufacturing executives said that supply chain disruptions had a significant effect on both productivity and profits.

Unfortunately, from a customer’s perspective, it doesn’t matter where the products were held up. Your customers hold you responsible when they can’t get what they want when they want it.

Imagine you forecast perfectly for Mother’s Day and order the right amount of inventory for your sales. What happens if one of your vendors can’t keep up with demand and delivers your products late? Or there might be a shipper strike, and the shipment languishes on a loading dock somewhere?

At the end of the day, when customer orders aren’t fulfilled on time, it’s still a negative experience for your brand, which lowers the chance of them becoming a return customer. It can also cut into revenue if customers cancel or return orders for gifts that didn’t arrive on time.

When your internal departments aren’t clear on what each other needs or your suppliers aren’t sure what you need, problems can snowball. During major sales seasons, when timelines get tighter and customer expectations are higher, miscommunication problems are especially harmful.

In situations where there are short-term spikes in customer demand, you need to know you can communicate and collaborate effectively internally and externally. The free and honest flow of accurate information helps ensure realistic expectations for everyone so that products and supplies arrive on time and are distributed as needed within your company so you can fulfill orders quickly.

If you can’t rely on your inventory management and order processing system, it’s almost impossible to forecast future demand accurately so that you can handle increased sales volume efficiently. Using spreadsheets or old technology to manage inventory isn’t just time-consuming; it can leave you with inaccurate data due to errors and inventory honesty issues and provides limited capabilities to integrate and scale.

Ultimately, inadequate technology solutions can result in sluggish operations and limit your ability to take advantage of seasonal demand changes.

At Cin7, we go beyond inventory management and focus on Connected Inventory Performance, which means making your data work for you across multiple sales channels and locations at all times.

Here’s how Cin7 Core can help you navigate the challenges of seasonal demand so you can capitalize on the sales opportunities that come with major shopping days and seasonal demand.

Systems like Cin7 Core ensure that you know your stock levels at all times and across all locations without the headache of juggling Excel sheets.

It can also analyze your inventory turnover ratio, lead times, and seasonal patterns to help you determine optimal seasonal inventory levels during busy seasons. With the right data, you can minimize out of stock products, reduce excess inventory, control costs, and improve customer satisfaction.

With Cin7 Core, you can better manage your labor and machinery resources for limited downtime. The software identifies all of the resources needed for production, including machinery, equipment, and laborers (either in groups or as individuals), and suggests schedules based on those needs so you can meet deadlines and future product demand without straining your resources.

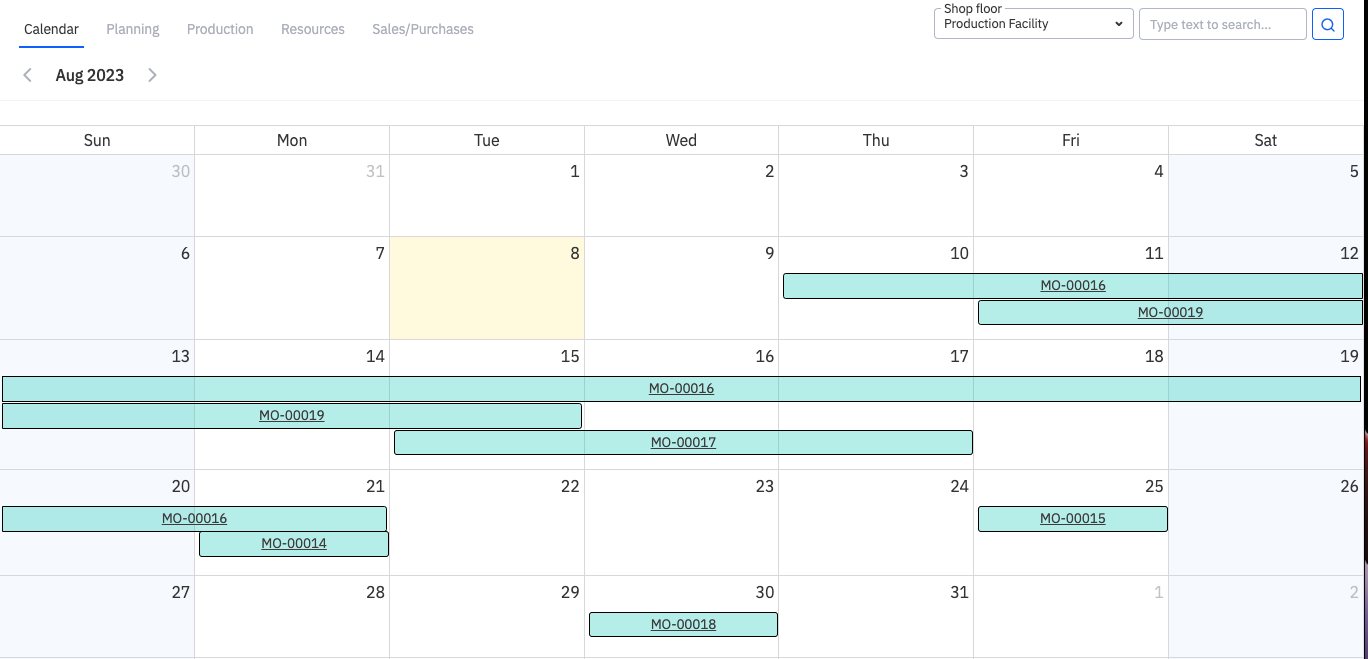

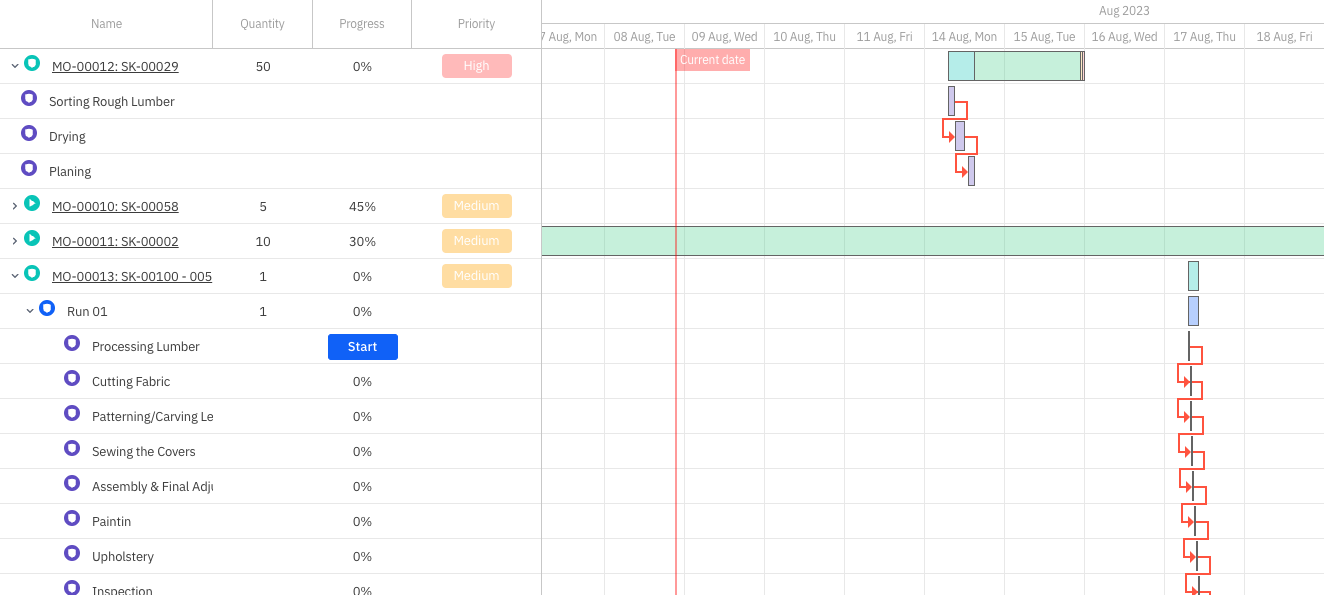

View your plan as a calendar or a Gantt chart to see the steps in the production process and visualize work orders already in the timeline. You can set a requested delivery date or planned start date, and the system works backward or forward to suggest the optimal work schedule for each order. You can also drag-and-drop the production order to change the start date. The system will prevent you from any rescheduling changes that would cause you to miss the required by date.

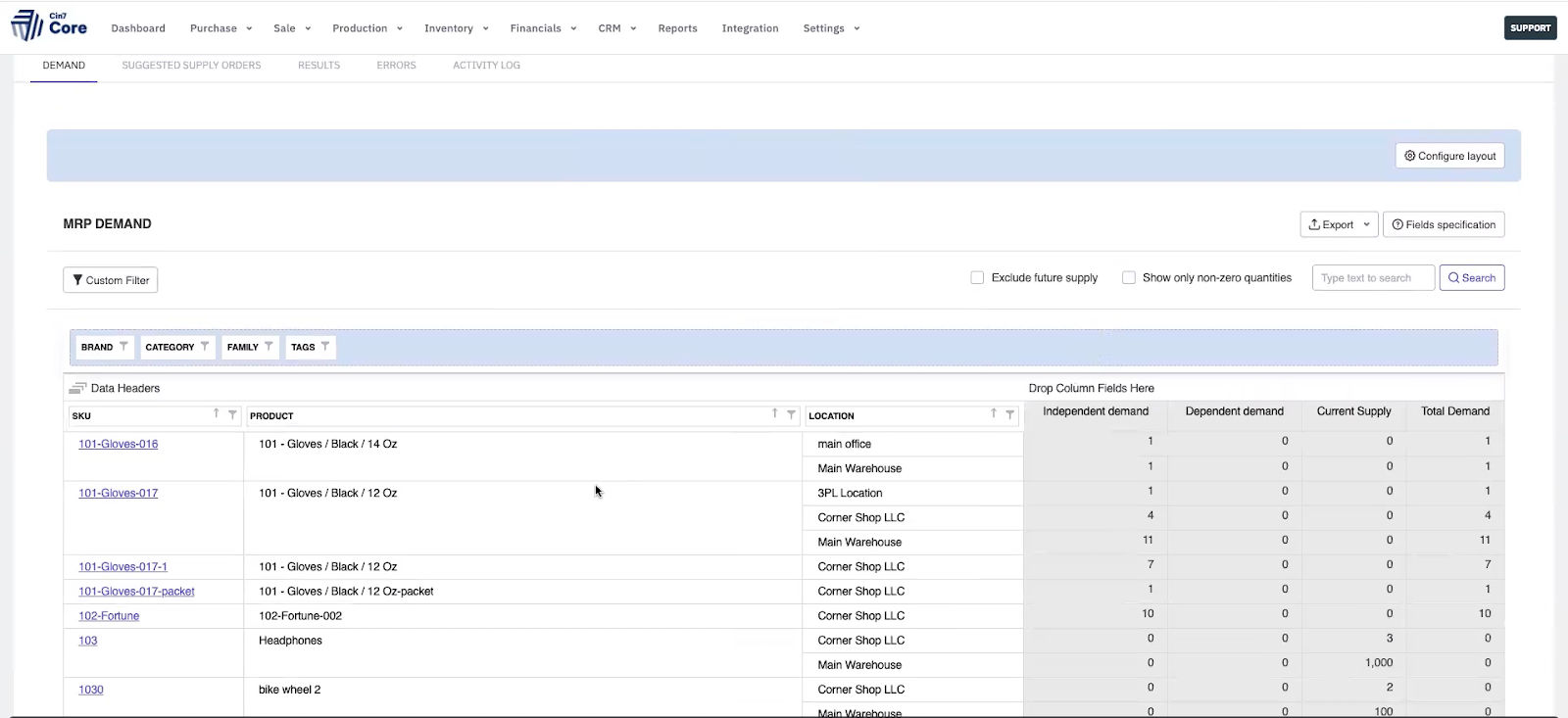

Using Cin7 Core’s material requirements planning (MRP) helps automate and optimize your planning and scheduling so you’re not relying heavily on manual processes. Automated MRP quickly transforms your production plan into a list of requirements for subassemblies, parts, and raw materials needed to create your final products, plus a schedule to get it all done.

The MRP system enables managers to analyze production data and accurately assess labor and supply requirements so they can make more informed decisions that streamline operations, enhance operational efficiency, and allow them to respond to quick spikes in demand effectively.

Proper inventory forecasting can help you better prepare for demand surges by using your existing data to estimate material requirements far before customers actually place their sales orders, giving you more time to prepare to scale operations.

Cin7 Core analyzes past sales data to identify patterns, trends, and seasonal shifts that improve forecast accuracy. By taking seasonality and metrics like lead time into consideration, the system helps improve production schedules and ensure material availability.

You can also combine Cin7 with Inventoro’s machine learning and AI-driven forecasts for even more accuracy. Inventoro is a powerful and user-friendly sales forecasting tool that provides advanced tools for small and medium businesses. By leveraging the power of AI-driven forecasting, product segmentation, demand planning, purchase order automation, and inventory optimization with the power of Cin7’s connected inventory and order management features, you can improve productivity while increasing sales volume and revenue.

Cin7 Core helps you take an automated and data-driven approach to your vendor and supply chain management. This way, you can identify which vendors are the most reliable and take their historical performance into account when you place inventory orders.

Regularly auditing vendors and analyzing historical data in Cin7 gives you valuable insights into lead times so you can make adjustments and maintain a positive customer experience.

Cin7 also partners with Anvyl so managers can have more supply chain visibility.

Using inventory software that can serve as one source of truth is critical for success, especially when demand is high and the pressure to deliver increases.

With Cin7 Core, teams within your company can turn to a single system for up-to-date information on production orders, work orders, current inventory levels, and more.

Cin7 Core puts information at your fingertips like:

Insights from real-time data allow you to communicate clearly and proactively address any issues so you can resolve them before they impact your customer service.

If you’re not prepared for the challenges of seasonal demand increases, holiday seasons can be incredibly frustrating for sellers. However, by recognizing the most common challenges and taking a proactive approach with powerful automation software, you can be confident in your ability to effectively manage inventory and production changes to satisfy your customers and capitalize on these spikes in demand.

Experience a free trial of Cin7 Core today and discover how the right solution can help you manage less and sell more, even in the most demanding of markets.

Lost, obsolete or overstocked inventory drives up costs and destroys margins. Without inventory visibility, you won’t know your business is suffering until it’s too late.

The year 2020 marked the highest-level Working Capital Index in 10 years resulting from the Covid-19 pandemic, reported J.P. Morgan. The findings highlight how real-world events impact inventory levels and the availability of working capital. Working capital is defined as inventory, debts, cash, and cash equivalents. A business needs working capital to be able to […]