Fans of “The Office” may remember when Michael Scott placed golden tickets into five different boxes — promising a discount to customers who received the tickets. A successful tactic? Not really. But it is an insightful glimpse of the challenges of managing a warehouse.

Comedic mishaps are unlikely in a real-life warehouse, but mistakes are bound to occur. When managing thousands of products, delivery dates, and incoming stock, human error will occur.

Warehouse management systems are abundant in 2023, many of which are designed to fit the specific needs of different industries. Recently, advanced technologies specifically designed to address warehouse management issues have emerged. With a comprehensive and efficient warehouse management system, a warehouse operating at optimum levels is within reach.

Stay with us as we break down the different types of warehouse management systems, the benefits of a WMS, and explore a few of the best options to explore.

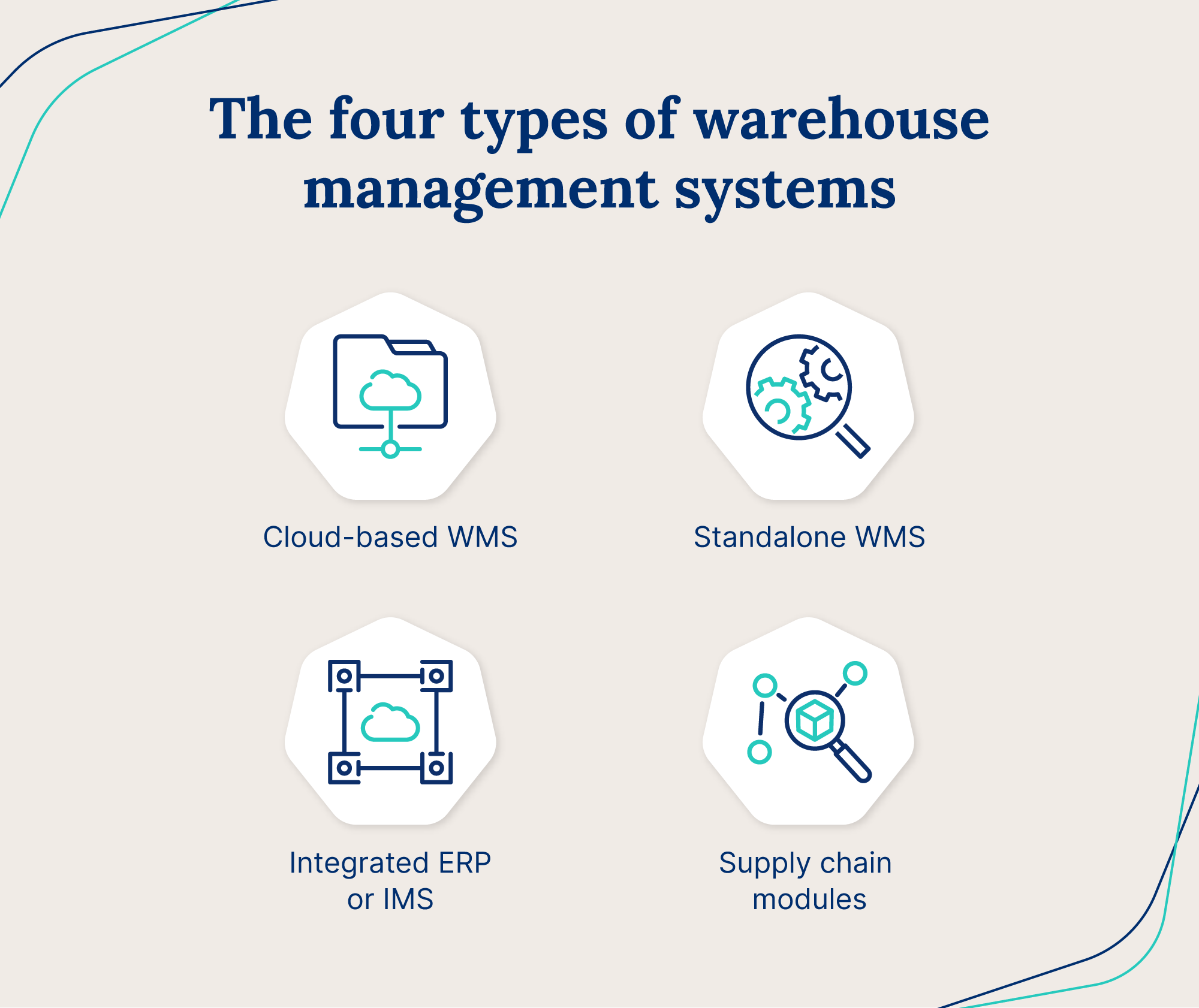

All warehouse management systems seek to accomplish the same goal, but there are a few key types of warehouse management software, which include:

A cloud-based WMS refers to software that is hosted by a vendor instead of on a company’s server — meaning businesses can take a completely hands-off approach to WMS software since the vendor handles and fixes all bugs and errors that may arise.

Typically, businesses will pay for a cloud WMS on a subscription basis. If you opt for an on-premise solution, you’ll face a high upfront cost because you’re responsible for hosting the solution. A Cloud-based WMS tends to be more cost-efficient and time-saving for businesses.

Learn more about what a cloud-based WMS can do for your business.

A standalone WMS is a software solution that’s sole function is to optimize warehouse efficiency and generally lacks features that work to optimize other business processes.

A standalone WMS differs from broader ERP solutions and inventory tracking software that include warehouse management as a feature in a larger library of tools. If you only need a tool that optimizes warehouse management, then a standalone solution is your best choice. However, if you’re looking to optimize processes like inventory management or accounting, a more comprehensive solution will give you the most bang for your buck.

Unlike a standalone WMS, an integrated ERP or inventory management software (IMS) generally includes warehouse management as a feature within a larger suite of tools. Integrated ERPs or inventory management software will typically manage your warehouse processes alongside accounting, invoicing, shipping, and supply chain management.

Integrated ERP or inventory management software also gives you insights about your company at a more granular level. Since the software manages the order process end to end, it can help you make data-driven decisions about restocking and order management.

Supply chain modules are warehouse management systems that integrate with supply chain platforms to provide a big-picture analysis of logistics and supply chains.

With this type of warehouse management system, you can easily make warehouse and logistics decisions concurrently as you can view the processes together. As a result, you can optimize processes more efficiently.

Warehouse management systems improve businesses’ efficiency by offering a few key benefits. Some of these include:

One of the most significant benefits of inventory management software and WMS is that they offer visibility into inventory from the second it arrives in a warehouse up until the moment it leaves. Through improved visibility, businesses can more accurately forecast demands and make data-driven decisions about different products — not to mention having improved traceability throughout the process.

Every great inventory management process is rooted in connection. You need a product that integrates with all your processes to connect aspects of the inventory lifecycle.

If you’re using an ERP or inventory management software (IMS) that features warehouse management, you’ll gain holistic insights that allow you to optimize warehouse processes for success.

Accuracy is key in inventory management and warehouse management, and mistakes often get made when dealing with large quantities of inventory.

Warehouse management systems use automation to eliminate manual errors when logging inventory data, thus improving efficiency and creating stronger processes.

Perhaps the most underrated, but also the most important, benefit of a WMS is improved customer relationships. When you optimize warehouse management, you speed up order fulfillment and improve the accuracy of orders. As a result, you get happier customers who are more likely to buy from you again.

While some ERPs, IMSs, and WMSs may be pricey, the best software solutions should save you money in the long run. Warehouse management systems help you optimize warehouse space, make informed decisions about which products to prioritize, and identify perishable or date-restricted products that must go off the shelves first.

As a result, the right system will help you better manage your inventory and your space, thus reducing waste and overall costs.

Growing companies should focus on efficient growth, and a WMS reduces time spent on manual day-to-day operations so you can think more about the company’s future.

Additionally, the best warehouse management systems scale with you, so they can adapt as your business grows. And with reduced time and money spent on warehouse operations, you can sell more at a lower cost.

If you need a warehouse management system, there are a few software you should consider immediately — if they make sense for your business. Here are five of the best warehouse management systems.

Cin7 provides comprehensive inventory management software with an integrated warehouse management system and WMS mobile app geared to help small and mid-size businesses with:

With visibility into every aspect of the product life cycle, Cin7 customers can assure accurate order fulfillment for their customers while optimizing their internal processes. Cin7’s warehouse management software is mobile-optimized, so customers can scan products at every stop.

Price: Starting at $325/month

Start a free trial of Cin7 to optimize your warehouse management today

Oracle’s WMS is a solid solution for enterprise companies looking for software with advanced features tailored to large organizations. Used by large wholesalers and retailers, Oracle’s product helps companies cut inventory costs, add new sales channels, boost productivity, and more.

Price: Available upon request

SAP’s Extended Warehouse Management software is a solid solution for enterprise companies looking to navigate complicated supply chain logistics and control large inventory volumes in their warehouse. Through automation, SAP takes most of the legwork out of manual processes.

Price: Available upon request

Another strong option for enterprise organizations, NetSuite’s WMS aims to help companies eliminate monotonous manual processes so they can sell more, deliver faster, and reduce costs. Especially for companies with multiple warehouses, Netsuite’s software makes it simple to manage complex processes.

Price: Available upon request

Manhattan’s WMS is constantly adapting to roll out new features and updates that adapt to the changing supply chain landscape. Manhattan claims to have a “unified” approach to warehouse management and gives customers control over fulfillment, labor, slotting, automation, and more.

Price: Available upon request

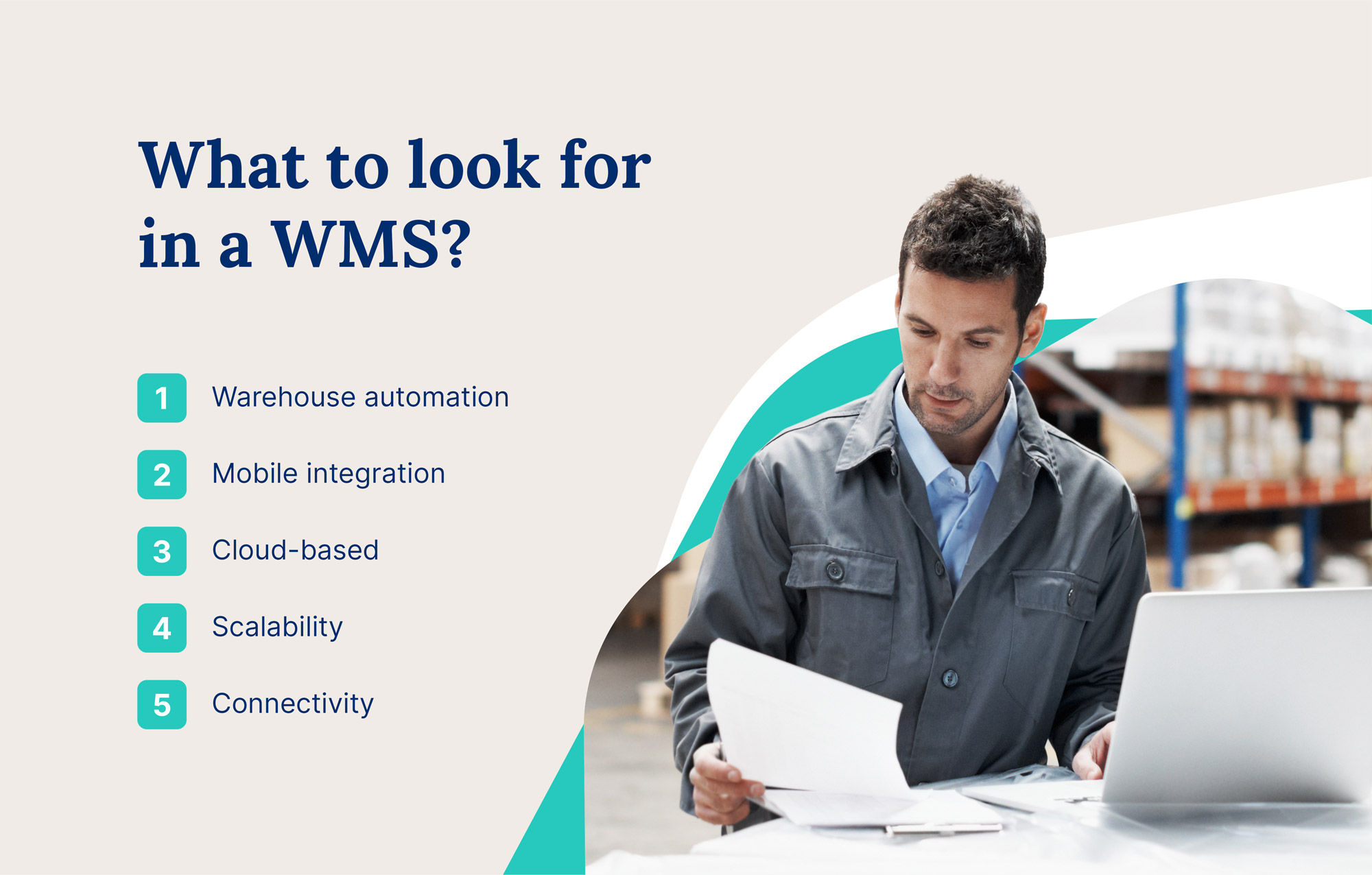

You should do careful research before investing in warehouse management software. Here are some key features you should look for when choosing a WMS.

Still have questions about warehouse management systems? We’ve got you covered. Here are some of the top questions and answers about WMSs.

The four types of warehouse management systems are standalone, supply chain management modules, built-in to an ERP or IMS, and cloud-based.

Cin7 Core is an example of an inventory management system with built-in warehouse management, meaning that it contains warehouse optimization features within a larger suite of tools. The benefit of integrated software like Cin7 is that every feature integrates — so you can enjoy a unified approach to inventory performance.

The difference between a warehouse management system (WMS) and supply chain management (SCM) is the scope of which they cover. SCM focuses broadly on the supply chain, while a WMS focuses specifically on managing a warehouse.

A warehouse management system is responsible for optimizing each part of the warehouse process, from when products arrive at the warehouse until they leave. The right warehouse management system should reduce time and costs and leverage automation to reduce manual labor and errors.

An effective warehouse management system will help a business’s bottom line and lead to higher and more efficient productivity. Monitoring the latest trends and innovations in warehouse management is imperative to staying competitive in an ever-changing inventory management landscape, and the right WMS will ensure you never fall behind.

Start a free trial of Cin7 Core today and see how a partnership with us can help save you money, time, and effort.

There’s more to running a warehouse than just piling inventory on shelves. The design of your warehouse can make or break your overall operational efficiency. Warehouse layouts need to be optimized for clear visibility, smooth transfer of goods, and easy equipment accessibility. And no one design will work for everyone. Most companies use one of […]

Warehouses can be hazardous. First, the items they hold are stacked high and close together to make the best use of space. Second, a lot of pickers and machinery are going back and forth between the aisles and up and down the storage bins all the time. If the items haven’t been stored properly, if […]

A manufacturer’s inventory is its lifeblood, the basic ingredients for whatever is being made. When it comes to storing materials in the warehouse, there has to be enough materials on hand at all times, and they have to be in good condition. If these requirements aren’t fully met, a factory could shut down. Therefore, managing […]