It’s no secret that global supply chains have experienced issues over the last few years. For example, the war in Ukraine increased the price of commodities like gas and oil, food products, and fertilizers across the globe in 2022. Hurricane Ian hit Florida in 2022 and led to port and rail transportation shutdowns. Port Tampa Bay alone had a “$17 billion economic impact.” In a global environment, procurement teams need to be creative and plan to stay ahead of disruptions and competitors.

So, what is procurement? In the broadest business sense, procurement is the process of sourcing and obtaining goods or services. Procurement begins with identifying business needs and ends with paying a supplier for goods and services. The process involves a lot of communication, strategy, documentation, and financial analysis. Procurement involves many stakeholders including:

- Suppliers

- Accountants

- Legal teams

- Product and manufacturing teams

- Procurement managers

We’ve outlined the four types of procurement, how the process works from start to finish, procurement software, and more. We hope this guide helps you consider the process and its impact on your business.

Why procurement is important for business

Procurement is important because it’s vital to a business’s ability to function. Without certain goods and services, most businesses cannot operate. Direct procurement addresses the core functions of a business, and indirect procurement addresses the less direct elements, such as rent and HR services. For example, car manufacturers need to procure goods such as steel, rubber, and plastic, as these raw materials are critical to their ability to create a product. Any changes in availability or cost can have a significant impact.

Since procurement takes up 40%-80% of a business’s external spending, even a small difference in cost can significantly affect profit. Strategic approaches to procurement can minimize the cost of goods sold and also mitigate potential supply-related issues and disruptions that can impact business performance, such as:

- Supplier delays

- Supply chain issues

- Increased cost of goods and services

Supply chain disruptions and market shifts are inevitable, and the global marketplace must respond to remain buoyant. For example, a sudden increase in fuel costs can impact the associated costs of transportation and storage. To mitigate the impact of those rising costs, companies might use procurement analytics to manage their potential risk and remain profitable. In fact, procurement analytics is becoming so critical to navigating a turbulent supply chain that the market is projected to reach $19 billion by 2023, according to a recent study by Verified Market Research.

4 types of procurement

The four types of procurement include direct, indirect, goods, and services. Whether procurement is direct or indirect depends on the type of product a business creates. For example, car manufacturers indirectly procure office supplies, but office supplies are not an integral element of a vehicle. On the other hand, an office supply store directly procures office supplies from a wholesaler. This is considered direct procurement because office supplies are core to their retail business. Procurement types are important for planning and prioritization.

Direct procurement

Direct procurement refers to the procurement of goods and services that are critical to a business. Think of direct procurement as “directly related.” These goods and services generally get procured in large quantities at a low frequency. In a broad sense, this encompasses anything a business needs for creating a finished product.

Examples of direct procurement include:

- Raw materials such as coal, metal, plastic, corn, lumber, and more.

- Semi-finished goods and works in progress, including computer chips, sugar, paper, and anything processed.

- Finished products that retailers purchase from wholesalers, such as t-shirts and candles.

Indirect procurement

Indirect procurement refers to the procurement of goods and services that are important but not critical to a business. These goods and services generally get procured in smaller quantities and at a higher frequency. Think of indirect procurement as “indirectly related” to the business. However, don’t be misled, these goods and services are just as vital for the day-to-day operations of a business.

Examples of indirect procurement include:

- Office supplies such as computers, task management software, pencils, and more.

- Operation consumables like lubricant, water, sewing machine needles, bobbins, and chemicals.

- Outsourced services such as maintenance services, marketing services, business consultants, and any third-party services that help the business function.

Goods Procurement

Goods procurement refers to the process of acquiring physical items, which can range from a simple lightbulb to a fleet of vehicles. Unlike services, goods require transportation and storage. It’s important to note that software is considered a good, while software as a service (SaaS) is considered a service.

Examples of goods procurement include:

- Raw materials such as tin, grain, cotton, and petroleum.

- Semi-finished goods like steel, canola oil, yarn, and sugar.

- Finished products such as smartphones, clothing, cooked sausages, or furniture.

- Software, including on-premise software and non-subscription software.

Services Procurement

Service procurement refers to the process of sourcing and purchasing services. We can categorize this type of procurement under indirect and direct procurement, depending on how critical the service is to the company’s core function.

Examples of services procurement include:

- Business consultants like legal consultants, operational consultants, and HR consultants.

- Marketing agencies such as advertising agencies, PR agencies, and digital marketing agencies.

- Building maintenance services that include janitorial, landscaping, HVAC.

- Software as a Service (SaaS) like Amazon Web Services (AWS), Salesforce, and Slack.

Procurement misconceptions

With such a complex subject, it’s no surprise that people frequently misuse the term procurement. In this section, we’ll explore some of the most common misconceptions surrounding the topic, how it relates to the larger inventory management lifecycle, and how to avoid any miscommunication.

Procurement vs. purchasing

Purchasing is a part of the procurement process, but isn’t interchangeable with procurement. The two terms often get mixed up because they both involve acquiring goods and services. However, procurement addresses larger business concerns like profitability, while purchasing addresses lesser concerns such as order costs.

The purchasing process involves creating purchase orders, auditing shipments, and making payments. This stage of procurement does not involve identifying business needs or selecting vendors.

Procurement vs. supply chain management

Procurement is a significant part of the supply chain lifecycle that supports creating a product, but we shouldn’t confuse it with the entire supply chain management (SCM) process. Procurement and SCM both support the creation of a product, meaning they’re both concerned with materials, vendors, and manufacturing.

The procurement process ends when all the materials are in place for creating a final product. Procurement isn’t directly involved in manufacturing, distribution, and retail locations.

Procurement vs. sourcing

Sourcing plays a crucial role in the procurement process. It starts once the business identifies its needs and seeks potential vendors, vets them, and chooses the best option to fulfill the business’s needs.

Sourcing is a very early stage of procurement. Once sourcing is complete, the purchasing stage of procurement can begin. This stage involves ordering, monitoring, receiving, and making final payments for goods.

Procurement vs. contract management

Contract management is part of the procurement process, which addresses vendor relationships, purchase orders, and payment for goods received. Contract management is the process of managing those agreements.

Contract management and procurement share the same goal of building positive vendor relationships, making contract management relevant to each stage of the procurement process. But the terms should not be used interchangeably.

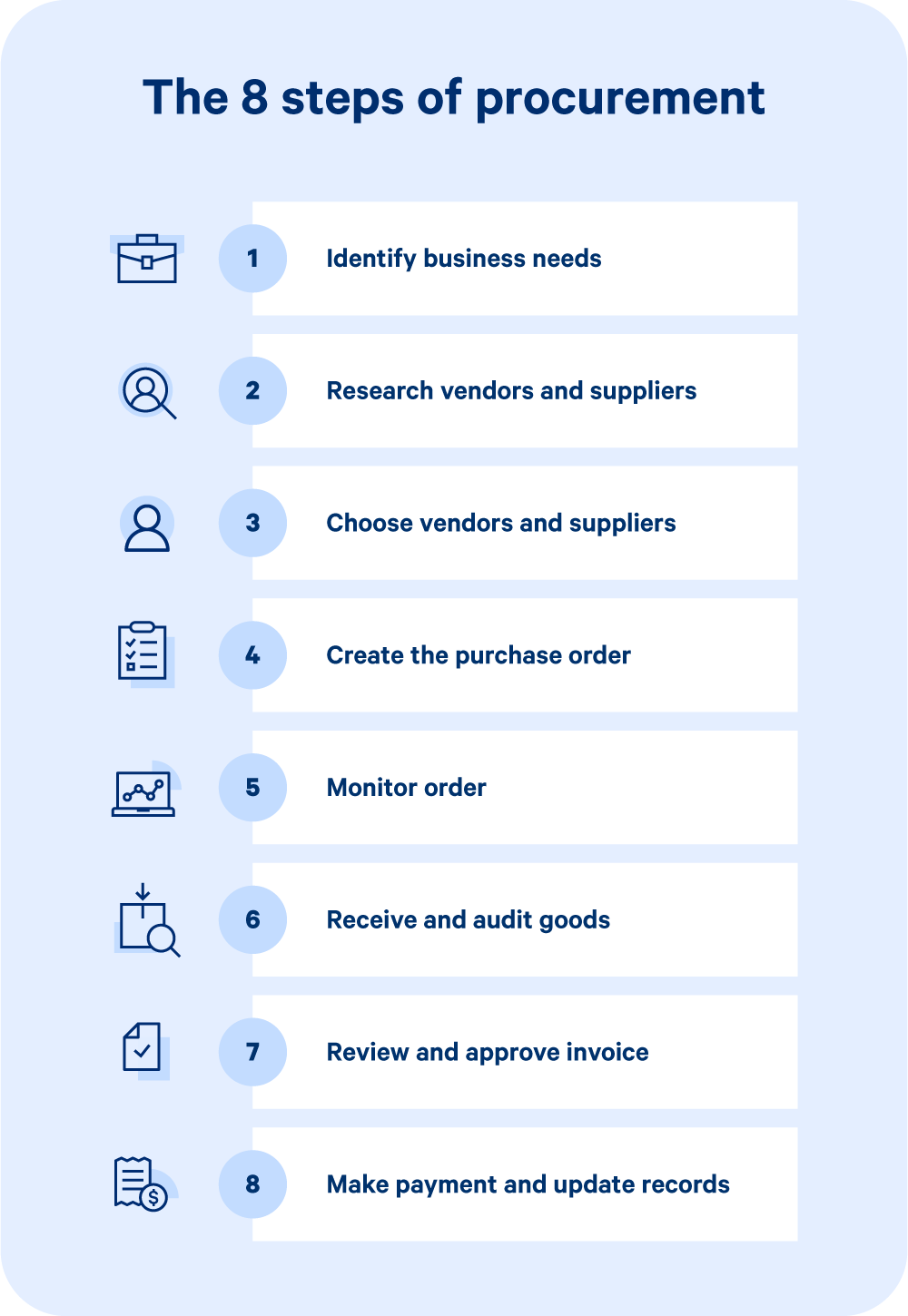

How the procurement process works (8 steps)

1. Identify business needs

This first stage of the procurement process identifies what a business needs to create a product or provide a service. Consulting with relevant stakeholders can ensure the satisfaction of all parties. This process is sometimes referred to as a business needs analysis (BNA).

These granular product details will inform sourcing and purchasing in the following stages. Departments make requests for a wide range of needs, which can range from raw materials to office buildings. The procurement process continues once the business has adequately identified its needs.

2. Research vendors and suppliers

Following the BNA, procurement specialists begin to research vendors and suppliers. Knowing what they require for products and services is only half the battle, as this research-heavy stage of procurement informs larger business strategies.

Vendor considerations can include:

- Cost of goods or services: How much the business will pay the vendor.

- Scope of the contract: How long the contract will last.

- Timing for payment: When to make payment.

- Termination requirements: What conditions can support the termination of the contract.

- Insurance details: Who will handle insurance during the transportation stage.

- Consequences: Details of the ramifications that can occur when contractual obligations are not fulfilled.

Strategy occurs during this stage using data analysis, market research, and supplier negotiation. This concept is known as strategic sourcing. For example, market research can inform a choice of suppliers from a particular geographic location, and internal demand data can support the choice of vendors and suppliers.

3. Choose vendors and suppliers

With all the necessary research in place, it’s time to choose vendors and suppliers. Before reaching out, the business will consider the budget and analyze the requested goods and services again. This stage includes validating the vendors before the business makes any commitments. This helps the business avoid potential scams, illegitimate claims, or other negative outcomes.

At this stage, the business will send a request for quotation (RFQ) to potential vendors. With an approved vendor quote, the business can send an official purchase order.

4. Create the purchase order

After selecting a vendor and receiving a quote, the business creates a purchase order (PO). Depending on its size and cost, the POs may require approval from various departments. Once approved, the PO is sent to the supplier.

Purchase orders contain important information, such as:

- An internal PO tracking number

- A description of goods being purchased

- Quality and quantity specifications

- Detailed vendor information

- Terms and conditions

- Payment terms and conditions

Once the vendor accepts the PO from a business, it becomes a legally binding contract between the two parties, complete with pertinent information. For example, the PO will indicate when the vendor receives payment from the business.

5. Monitor order

The order will be monitored as the supplier fulfills it, and as it moves through transit towards the paying business. Orders in transit can get lost, damaged, or delayed, and businesses and suppliers will share these supply chain visibility concerns. With so many stakeholders, it’s important that procurement specialists communicate diligently.

Procurement specialists and stakeholders need to prepare for:

- Receiving the order

- Auditing the order

- Storing the order

Businesses need to monitor shipments so relevant stakeholders can stay informed and prepared. The monitoring process begins with the creation of a purchase order. From there, procurement will stay in contact with the supplier who will send advanced shipping notifications (ASNs). The ASN is a document that provides all the necessary details about the incoming order, allowing the business to stay informed and keep track of their order.

6. Receive and audit goods

You must audit received goods for quality control and to ensure all agreements have been met. Document irregularities in case of vendor error or fraud. An internal auditor, or auditing team, will be in charge of the auditing process, and the PO will assess whether the goods meet expectations.

The PO will help answer questions like:

- Were all ordered goods received?

- What is the quality of the goods?

- Was the order received on time?

Detailed documentation is vital for informing the final phase of procurement. You can’t release payment for the order without a successful audit and an approved invoice.

The auditing process can provide useful insights to improve a business’s efficiency and profitability. Insights made during the audit can be compared against internal departments and external trends in the market.

7. Review and approve invoice

The invoice and PO are different documents that serve separate functions. The invoice is the document that needs approval before a vendor receives payment. While the PO is made available when receiving goods, the invoice may arrive at a later date.

Once they receive an invoice, the accounting team will typically perform three-way matching. Three-way matching ensures the PO matches the order receipt and invoice.

This stage ensures that:

- Payment is deserved (following audit)

- Payment is only for the items received

- Negotiated discounts will be honored

- Funds will be dispersed correctly

8. Make payment and update records

Payment is finally issued upon the approval of accounts payable. Businesses need to have an efficient approval process in place to ensure invoices are paid in a timely manner. Both parties have stipulations outlined in the final purchase order.

It is absolutely important to keep these records updated. Businesses must be prepared for potential audits or contractual disputes. Well-maintained records can also support data analysis. These accounting records may inform strategies, and can help improve inventory management, vendor relationships, and the procurement process overall.

What is procurement software?

Procurement software streamlines and simplifies tasks associated with the procurement process. Procurement software simplifies redundant manual tasks and increases efficiency simultaneously. The right software can make data accessible and help improve business efficiency.

Our inventory management platform provides robust reporting for small and medium-size businesses. And Cin7’s ability to integrate with commerce platforms makes it an all-in-one system for product sellers.

Sign up for a free trial to see how Cin7 Core can help you reach your business goals quicker and easier.

More from the blog

View All Posts

Essential e-commerce technology trends to implement in 2024

Read More

Why Your Digital Agency Needs Cin7 (And How to Make Money Doing It)

Read More